Types Of Hydrogen Storage That Can Be Used In The Future

Hello guys, welcome back to our blog. In this article, I will discuss the types of hydrogen storage that can be used in the future storing hydrogen, and I will also explain the effects, and characteristics of hydrogen.

If you have any electrical, electronics, and computer science doubts, then ask questions. You can also catch me on Instagram – CS Electrical & Electronics And Chetan Shidling.

Also, read:

- SoC Estimation Using Extended Kalman Filter In MATLAB Simulink

- What Is Kalman Filter, Types, Applications, Algorithms For Kalman Filters

- A Definitive Learner’s Guide For Electric Vehicle Technology Enthusiasts

Types Of Hydrogen Storage

Before examining some methods of hydrogen storage, the effects, and characteristics of hydrogen must be noted. Hydrogen is the easiest and most plentiful element in the Galaxy. It is hygienic and pollution-free:

- It is colorless, odorless, and has no flavor.

- It is the most delicate of all elements (molecular weight = 2.016g/mol). Its viscosity is about 14 times less than air (0.08376kg/m³ at normal temperature and pressure), and it has a significantly high diffusion rate.

- It is fluid at temperatures below 20.3K at atmospheric tension. The density of the liquid is 70.8 kg/m³.

- It includes the most elevated energy per unit mass of all fuels (HHV = 141.9MJ/kg or 11.89MJ/m³, and LHV = 119.9MJ/kg or 10.043MJ/m³). One pound of hydrogen has three periods the energy range of one pound of gasoline.

- It has tiny molecular size, letting it leak more easily via porous materials than other ordinary gases at equal pressures. At the exact holes or joints, it is leaking approximately 1.26 to 2.8 times faster than natural gas.

- It is naturally non-corrosive and non-reactive with standard container materials.

- It is non-toxic and non-poisonous. In distinction, the combustion by-products of diesel and other conventional fuels are better toxic from an inhalation perspective.

When an energy design is totally founded on renewable or irregular power systems, the situation arises that the energy need pattern cannot be completely fulfilled by online power generation. An energy storage method must be put in between energy generation and energy utilization. Hydrogen has been presented as the essential medium for cracking this problem.

Hydrogen is not a direct energy source, but it is operated as an energy carrier between energy generation and energy utilization. Power is developed from hydrogen either by the transformation in a fuel cell or by an explosion in internal combustion or turbine engine. In this dissertation, a hydrogen fuel cell design will be examined in detail.

Hydrogen is represented by a low density under standard conditions so its storage is challenging compared with liquid fuels. It can be stored in numerous basic structures such as (1) pressurized (packed) hydrogen gas in tanks or in subsurface reservoirs; or (2) liquid hydrogen in slim microspheres; or (3) Metal hydride combinations, i.e., H2 is kept in a metal or an alloy. The different storage classes have various characteristics. The preference of a specific storage type relies on these characteristics, and especially on the energy density and price of each type. let’s see the types of hydrogen storage.

Types Of Hydrogen Storage

01. Compressed gaseous hydrogen storage

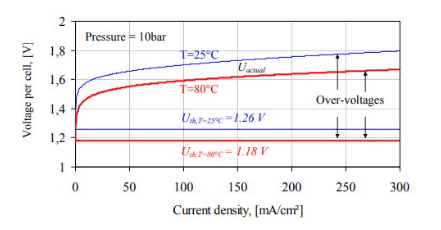

Condensed gaseous hydrogen can be kept in pressure tanks at ambient temperature and 200 up to 700 bar pressure. The numerous common materials utilized for hydrogen tanks are steel and aluminum. Of all storage technologies, condensed gaseous hydrogen has the most extended history and cheapest price. This repository type is right for electrolyzers, which can make hydrogen at elevated pressures.

The academic gravimetric energy density of hydrogen can be estimated by the molar mass of the hydrogen molecule (2.016g/mol) to be 39.4kWh/kg. The actual gravimetric energy density of reserved hydrogen is primarily dependent on the material of the container since light materials usually do not tolerate pressure as well as weightier ones. With a standard steel tank, an energy density of approximately 0.45kWh/kg could be completed, which is comparable to 1.14% of the weight of reserved hydrogen.

The material effect of tanks has taken a massive step with the growth of other composites. Thus, with these composite tanks, the energy density is improved to 4.45kWh/kg, which is equal to 11.3% of the weight of stored hydrogen. Compressed gaseous hydrogen can be kept either in above-ground portable or fixed tanks or in various types of earth caves. The aboveground hydrogen storage tanks range in size but are generally in standard pressure. One of the most useful properties of the aboveground tanks is that they do not spread.

The losses of the storage capacity are thus almost non-existent. Some leaks may occur via connectors but with good fittings and controllers, these leaks could be underestimated. The underground caves are an uncomplicated and relatively inexpensive method for large-size storage of hydrogen. The pressure in earth caves ranges between 80-160 bar and therefore the volumetric energy density is about 250-465 kWh/m³. The losses generated by the leaks in earth caves are approximately 1-3% of the entire volume per year.

02. Liquid hydrogen storage

Fluid hydrogen has been utilized as a fuel in space technology for many years. It is lightweight and has more irregular possible risks in terms of storage pressure compared with condensed gas. The hydrogen softens to a colorless liquid at –253°C (20.3K) and therefore the storage tanks need sophisticated insulation methods. Liquid hydrogen is kept in standing or lying tanks of 3-75m³ under the tension of 12 bar. The energy required to soften the hydrogen is about 20 to 30% of the energy range of hydrogen.

This is one of the biggest issues regarding the usage of liquid hydrogen. Yet, this loss of energy is completely balanced with a high energy density of liquid hydrogen. A portion of 1%/day of the stored hydrogen must be evaporated to maintain the lower temperature. The gravimetric storage viscosity of the liquid hydrogen in storage receptacles is about 25.9 wt.% (10.2 kWh/kg) and the volumetric energy density is approximately 2760kWh/m³. The advances in insulation methods and pressurization of the tank will have some impact on these figures. This kind of storage has quickly refueling (a 125-liter tank of liquid hydrogen can be refueled within just 3 minutes).

03. Metal hydrides storage

A unique way of hydrogen storage is accomplished by utilizing metal hydride. Metal hydride is a metal or an alloy, which is capable to bind hydrogen chemically. This metal or alloy can store numerous hundreds of its ability of hydrogen. When a hydride is created with a metal or an alloy, heat is developed, i.e., the method is exothermic. Contrarily, in demand to release hydrogen from a metal hydride, heat must be provided, i.e., the method is endothermic. These functions can be described by the subsequent chemical reactions

Charging or Absorption process: M + xH2 ⇒MH2x

Discharging or Desorption process: MH2x ⇒M + xH2

where M denotes the hydriding substance, a metal, or an alloy. The rate of these responses grows with the surface area. Thus, in general, the hydriding substances have utilized a powder to speed up the reactions. MH is the metal hydride, and X is the ratio of the numeral of hydrogen atoms to the numeral of hydriding substance atoms. During the construction of the metal, hydride hydrogen molecules are separated and hydrogen atoms are inserted in areas inside the lattice of the metals or alloys. In such a manner sufficient storage is made similar to the density of liquid hydrogen.

Yet, when the group of the metal or alloy is brought into account then the metal hydride gravimetric storage density is similar to the storage of pressurized hydrogen. The best possible gravimetric and volumetric hydrogen storage viscosity is about 0.07kg/kg of metal, and 101 kg/m³ of metal respectively, for a high-temperature hydride such as MgH2. Also, the gravimetric and volumetric energy storage viscosity of this metal hydride are 2.8kWh/kg and 4000 kWh/m³, respectively. During the storage method (charging) heat is removed which must be released in order to complete the continuity of the reaction.

During the hydrogen release cycle (discharging) heat must be provided to the storage tank. Two methods can be utilized for storing electric power in hydriding substances. In one of the ways, DC energy is utilized to electrolyze the water, and the hydrogen created is stored in a hydriding substance. When electric energy is required, the hydrogen is discharged from the hydriding substance by heating and utilized in a fuel cell to produce DC energy.

The heat from the fuel cell can be utilized to release hydrogen from the metal hydride. In the second strategy, one electrode of the electrolyzer is shielded with a hydriding substance. During the electrolysis of water, the hydrogen created on the electrode surface is instantly fascinated by the hydriding substance surrounding the electrode.

Then, when electric energy is required, the electrolyzer works in a reverse mode as a fuel cell utilizing the hydrogen discharged from the metal hydride to produce electric energy. The metal hydride method is costly and sensitive against contaminants and has a finite lifetime. On the other hand, this type of storage is fairly safe because the hydrogen is affixed to a metal.

This was about “Types Of Hydrogen Storage“. I hope this article may help you all a lot. Thank you for reading.

Also, read:

- 10 Tips To Maintain Battery For Long Life, Battery Maintainance

- 10 Tips To Save Electricity Bills, Save Money By Saving Electricity

- 100 (AI) Artificial Intelligence Applications In The Automotive Industry

- 100 + Electrical Engineering Projects For Students, Engineers

- 1000+ Control System Quiz, Top MCQ On Control System

- 1000+ Electrical Machines Quiz, Top MCQs On Electrical Machines

- 1000+ MATLAB Simulink Projects For MTech, Engineering Students

- 50 Tips To Save Electricity At Home, Shop, Industry, Office

Author Profile

- Chetu

- Interest's ~ Engineering | Entrepreneurship | Politics | History | Travelling | Content Writing | Technology | Cooking

Latest entries

All PostsApril 29, 2024Top 11 Free Courses On Battery For Engineers With Documents

All PostsApril 29, 2024Top 11 Free Courses On Battery For Engineers With Documents All PostsApril 19, 2024What Is Vector CANoe Tool, Why It Is Used In The Automotive Industry

All PostsApril 19, 2024What Is Vector CANoe Tool, Why It Is Used In The Automotive Industry All PostsApril 13, 2024What Is TCM, Transmission Control Module, Working, Purpose,

All PostsApril 13, 2024What Is TCM, Transmission Control Module, Working, Purpose, All PostsApril 12, 2024Top 100 HiL hardware in loop Interview Questions With Answers For Engineers

All PostsApril 12, 2024Top 100 HiL hardware in loop Interview Questions With Answers For Engineers